Who are we?

Agenma B.V. specializes in the overhaul of pumps with our main focus on improving the availability of your rotating equipment and minimizing production downtime.

Our other activities include inspection, technical advising and maintenance services.

Our clients include companies operating in the chemical, packaging, food and waste management industries.

They look to us as a cooperative partner. Reliable, accessible and service-oriented.

Another important branch of our business concerns the sale of pumps.

We have over 2000 pre-owned pumps in stock to be overhauled and tested to your specifications.

Agenma B.V. has been founded in 1996 and is located near the Belgian border in Hoogerheide where our activities are carried out in our workshop.

Situated along the Rotterdam - Antwerp transport axis: at the crossroads of Europe.

We are at only 50 km distance from both world ports.

Our 280 m2 workshop is fully equipped with lathe, milling, drilling machines and crane with SWL (save working load) up to 5 tonne.

The shop consists of balancing, welding, grinding and sandblasting facilities together with a self-contained disassembly and cleaning room.

We are interested in long-standing relationships with our customers.

Based on mutual trust and our hands-on mentality. You can expect from us a solution-oriented approach whereby long-term value development is more important than short-term gains.

Agenma B.V. has 20 years of experience necessary to manage your assets by providing support services that will enable safe, reliable and cost effective operation.

OUR SERVICES

Retrofit

Retrofitting can be the solution when increased operating conditions are demanding more from your pump.

To retrofit pumps used in critical applications which suffer from poor reliability can reduce the risk of unplanned outages, improving the reliability of your system.

Pump Sales

Our company sells new, reconditioned and refurbished pumps.

These pumps are being refurbished/overhauled and tested after your specifications in our workshop.

This gives you the opportunity to save on your investment while choosing a quality pump best suited for your system.

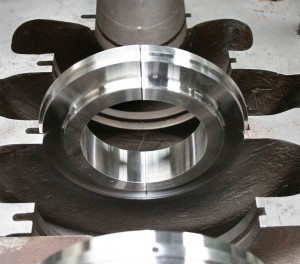

Repair / Overhaul

We offer you services ranging from standard inspections and repairs to

complete overhauls.

Equipment repair are being carried out at our workshop in Hoogerheide.

WHAT MORE DO WE PROVIDE

On-Site Projects

If the technical advice shows that changes are necessary to improve the reliability of your process, we are very capable to do that for you.

Eco Friendly

Agenma B.V. makes a continuous effort to minimize its impact on the

environment and promote environmental awareness.

We realise that in order to cut our carbon footprint we have to behave in a

environmentally responsible manner and reduce waste through re-use and recycling.

Technical Adivice

When pumps have to be overhauled more often than would be expected, this is

usually caused by a combination of factors.

Drawing on 20 years of experience and knowledge we can advise and assist you with our hands-on and services-oriented mentality.

LET’S GET INTO DETAILS….

Repair and Overhaul

We offer you services ranging from standard inspections and repairs to

complete overhauls.

Equipment repair are being carried out at our workshop in Hoogerheide.

After a thorough inspection is completed, a full report of the pump’s condition

can be drawn up.

When overhauling pumps to ‘as new’ condition, the following points are addressed:

– Overall condition

– Detailed examination of all critical parts and their condition

– Proposal for materials upgrade

– List of parts suitable for re-use or refurbishment

– List of parts to be replaced

– Estimate of time and cost of work needed

Our in-house services include:

Minor/Major Overhauls & Repair

Bearing And Seal Changes

Dynamic balancing

Reconditioning

Pump Sales

Our company sells new, reconditioned and refurbished pumps.

These pumps are being refurbished/overhauled and tested after your specifications in our workshop.

This gives you the opportunity to save on your investment while choosing a quality pump best suited for your system.

Besides that, there is another important reason for choosing pre-owned pumps.

It is clear that such a choice results in economical reuse of raw material and energy reduction.

You save money on the purchase of pumps with less impact on the environment.

As we are not affiliated to any brand we can give you a unbiased advice.

Once we understand the process, our focus is to make sure you will be

fully informed and make best practice decisions.

Retrofit

Retrofitting can be the solution when increased operating conditions are demanding more from your pump.

To retrofit pumps used in critical applications which suffer from poor reliability can reduce the risk of unplanned outages, improving the reliability of your system.

The opportunity for retrofit can occur in many applications.

Some examples:

• Excessive seal leakage due to low specific gravity applications .

• Frequent seal failures due to shaft deflection.

• Seal failure due to process changes.

• Pumps with insufficient designed shafts or bearings causing vibration problems.

• Chronic bearing problems resulting in high temperature issues.

• Bearing damaged caused by VFD induced shaft voltages.

Benefits of retrofitting are:

• Short downtime as compared to a new pump.

• Eliminating engineering and the need to modify existing piping or foundation, saving you time and money.

• Improving pump reliability and reducing maintenance costs.

• Reduce energy consumption.

Technical Advice

When pumps have to be overhauled more often than would be expected, this is

usually caused by a combination of factors.

Equipment failure occur in 70% of all cases due to:

– System design

– Improper installation

– Insufficient or lack of maintenance

– Incorrect start-up and shutdown procedures

Drawing on 20 years of experience and knowledge we can advise and assist you with our hands-on and services-oriented mentality.

– Proposals for materials or design upgrades.

– Recommendations for process or operational changes if applicable.

– Directions for changes in operation and maintenance procedures.

– Discuss the best options to avoid premature repairs in the future.

– Practical advice to make best practise decisions.

Eco Friendly

Agenma B.V. makes a continuous effort to minimize its impact on the

environment and promote environmental awareness.

We realise that in order to cut our carbon footprint we have to behave in a

environmentally responsible manner and reduce waste through re-use and recycling.

When the situation permits we will use recycled, recyclable products and

materials where these alternatives are available, economical and suitable.

We strive for the reduction of our electricity consumption

Therefore we generate our own energy by using solar power.

When using solar energy, the environment is harmed less.

It is a renewable CO2-free form of energy generation.

Even our hot tap water is provided by solar heat.

Of all water on Earth less than 3% is fresh. Over 2.5% is frozen, distributed in places like Antarctica, the Artic and glaciers, consequently not available to man. We must rely on this remaining 0.5% for meeting all of humans and ecosystem’s fresh water needs.

So reduced water consumption is yet another goal for us to achieve.

At this moment we are working on collecting rainwater to be used in our facility So we can not only save on but also reduce our tap water use.

Pumping systems account for nearly 20% of the world’s electrical energy consumption.

So in order to minimize our carbon footprint it’s important to reduce, re-use and recycle.

Even if an overhaul costs 75% of the new price it is better for the sake of our environment to overhaul than to purchase a new pump.

So think about giving your pump a second life!

On-Site Projects

Agenma B.V. has the opportunity to offer you on-site project support.

• Reliability increase: Improving maintenance procedure of your assets, upgrading machinery and rotating equipment.

• Process-upgrades: Installing new pumps and machines for meeting new process demands

• Equipment changes: Modify piping or construction when required for installation of new plant upgrades.

• Shut down: Getting existing equipment back up and running during system changes

• Safety and environment: Comply with stricter regulations, reduce energy consumption and water usage.

We can manage projects from start to finish or work with our customers at various stages.

Our strength is to focus on technical improvement, reliability increase and economic optimization.